Business Details

KOEI TOOL operates in two primary business segments. The first is 「Tooling Business」 which involves the design and manufacturing of plastic injection molds. The second segment is 「AM Business」 where metal 3D printing technology is utilized on designing and fabricating of gas venting products and cooling inserts.

Tooling Business

Manufacturing of plastic injection molds

Factories in Osaka, Singapore, Thailand, Indonesia, Malaysia, and Vietnam. Utilizing the design and production capabilities within the group, which offers new mold construction services at overseas factories. This coordinated approach allows us to handle a large number of new mold constructions. We specialize in intricate resin parts and high-precision molds, including double-color injection molds and heat & cool molds.

AM Business

Gas venting proposal 「GASEXIT」for injection defect prevention.

Develop, manufacture, and sell the patented gas venting insert「GASEXIT」 that effectively addresses defects in injection molding. Utilizing the fine porous material with the property of allowing gas to pass through but making it difficult for resin to flow in. It contributes to extending the maintenance cycle of molds and improving the durability in turns of shot counts.

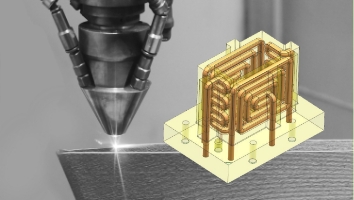

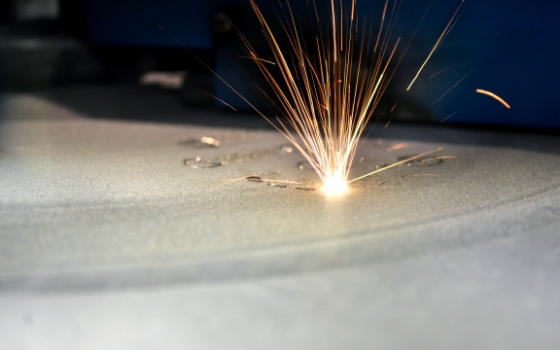

Metal 3D printing services available.

Actively improving powder bed fusion technology with two high-precision metal 3D printers capable of achieving fine details. Ideal for creating intricate internal structures and precision molds that are difficult to achieve through traditional machining methods. Turnkey solutions from modeling and analysis to manufacturing.

More about KOEI TOOL

Contact

Use the web form for inquiries or quotations.

Please referred to the frequent Q&A before request your inquiries.