- ホーム

- HOME

- Business Details

- Manufacturing Services for Metal 3D Printing

Manufacturing Services for Metal 3D Printing

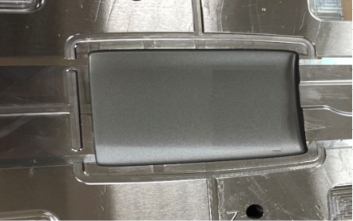

Design and fabrication services for cooling inserts and other components utilizing metal 3D printing technology. Seamless turnkey solutions from modeling to analysis and fabrication.

Modeling, Analyzing and Custom Shapes Manufacturing

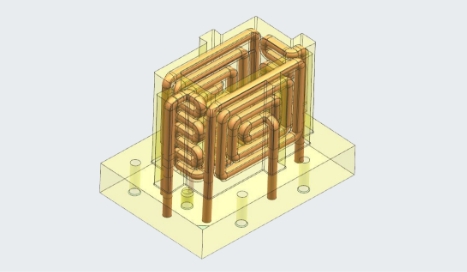

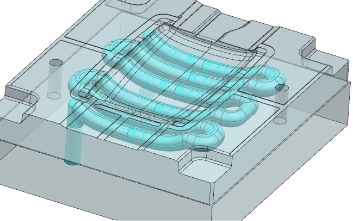

KOEI TOOL also offers manufacturing services utilizing metal 3D printing, specifically for conformal cooling inserts and specialized parts with complex shapes that are difficult to produce through conventional machining methods.

Features of Custom Manufacturing

POINT 01

High-Precision Manufacturing

High-precision 3D printing using the powder bed fusion method. It's ideal for creating intricate internal structures and precise molds that are challenging to achieve through conventional machining.

Equipment Specification OPM250L

| Maximum Tooling Size W×D×H | 250 x 250 x 250 |

|---|---|

| Laser type | Yb Fiber |

| Maximum laser output (W) | 500 |

| Scanning speed (mm/s) | Max.2600 |

| Spot diameter (mm) | 0.1〜0.6 |

| Maximum spindle rotation speed (min-1) | 6000 ~ 45000 |

| Cutting precision (μm) | 0.1 |

| Laser precision (μm) | ±30 |

| Powder type | Maraging |

| Hardness/HRC (after hardening) | 31-37(51-57) |

POINT 02

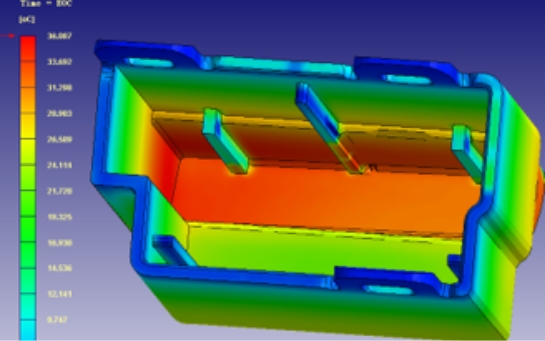

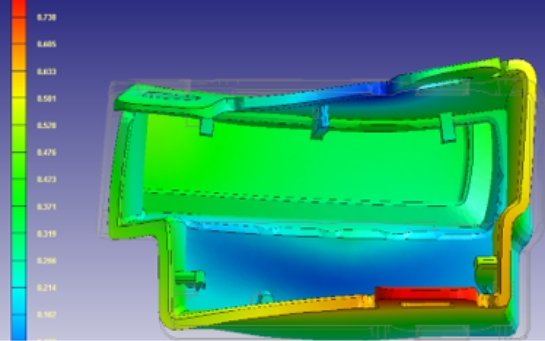

CAE Analysis in Addition to 3D Modeling.

Capable of 3D model designing with only 2D drawing or only concept sketches, saving customers’ trouble of designing. Utilize CAE analysis such as flow analysis, stress analysis, and generative design in addition to deliver optimized product designs.

POINT 03

Turnkey Support Until Finishing.

Comprehensive range of manufacturing equipment within the KOEI TOOL GROUP, leverage the company expertise as a mold maker to provide precise finishings.

Mirror finishes up to #3,000 grit, capable of performing texture finishes, eliminating the need for additional post-processing on the customer's end.

POINT 04

Feasible for SKD61

Capable of production conformal cooling inserts with SKD61 that traditionally challenging due to cracking issues. This capability extends to various applications, including die casting.

For Inquiries of Manufacturing Services.

Feel free to consult with metal 3D printing designs. Turnkey service from modeling, analysis, and the complete fabrication process.

Contact

Use the web form for inquiries or quotations.

Please referred to the frequent Q&A before request your inquiries.