- ホーム

- HOME

- Products Information

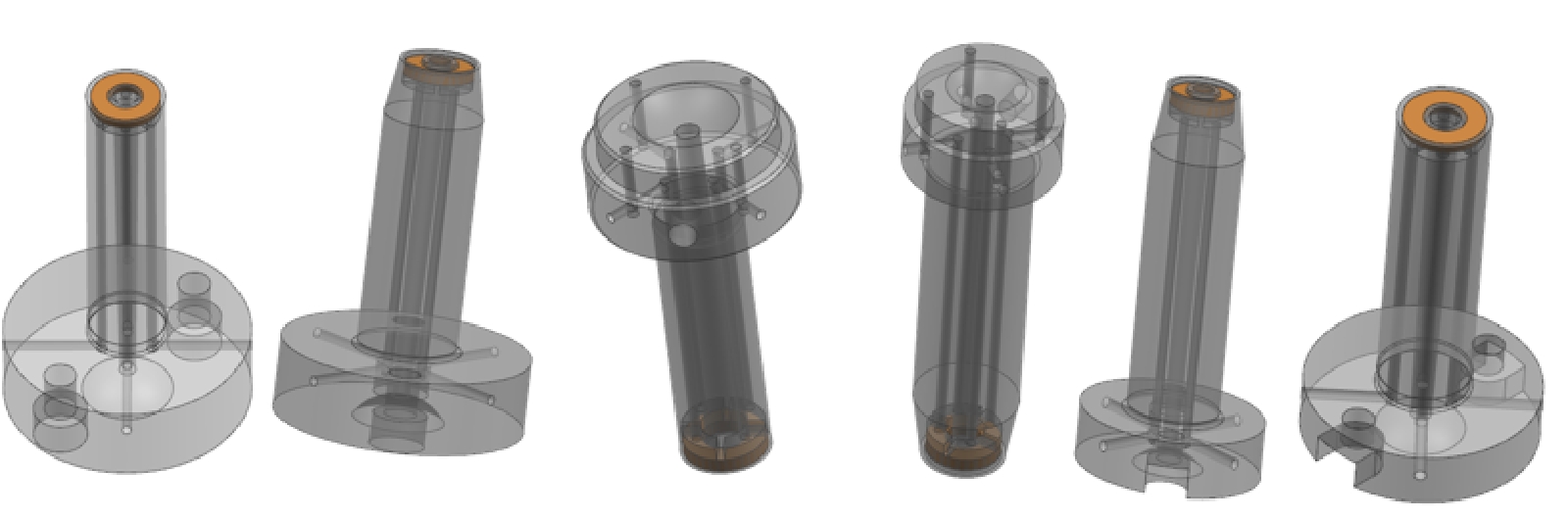

- GASEXIT BUSH

GASEXIT BUSH

Gas Venting Solution at Sprue End

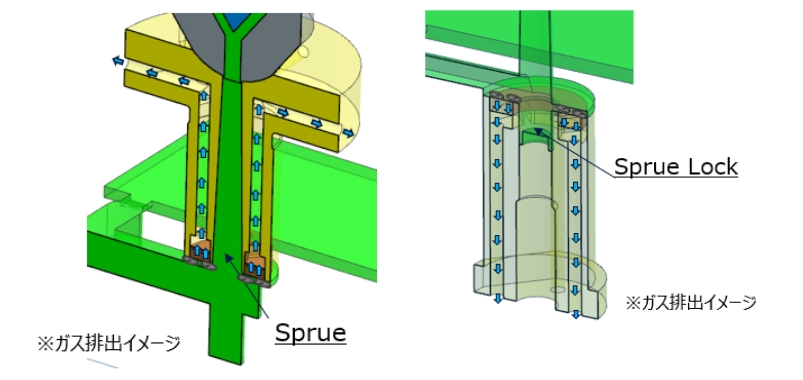

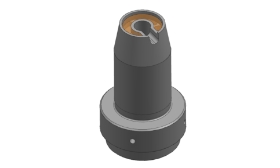

GASEXIT BUSH is a sprue bush / sprue lock bush that discharges gases from the sprue end part.

【Patent pending】

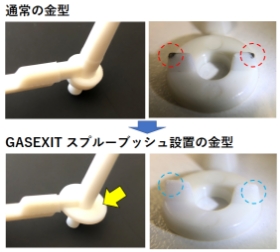

Isn’t there a large amount of gas tar stuck to the sprue bush during mold maintenance?

This is because the gas accumulated in the nozzle is exhausted outside the mold from the gap between the bushes.

However, the gas tar will stick to the gap between the bushes after production has been done for a while, causing the gas to flow into the product surface, generating product defects.

GASEXIT BUSH is a product that can most efficiently discharge the gases accumulated in such nozzles.

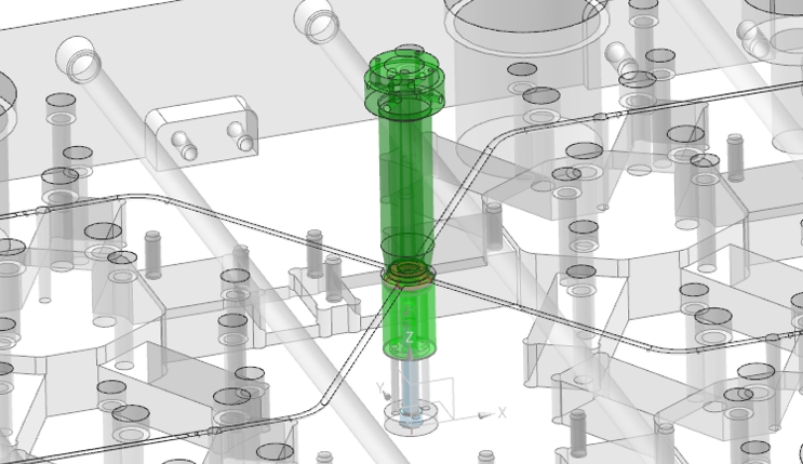

Gas venting image

Gas venting image clip

GASEXIT BUSH features

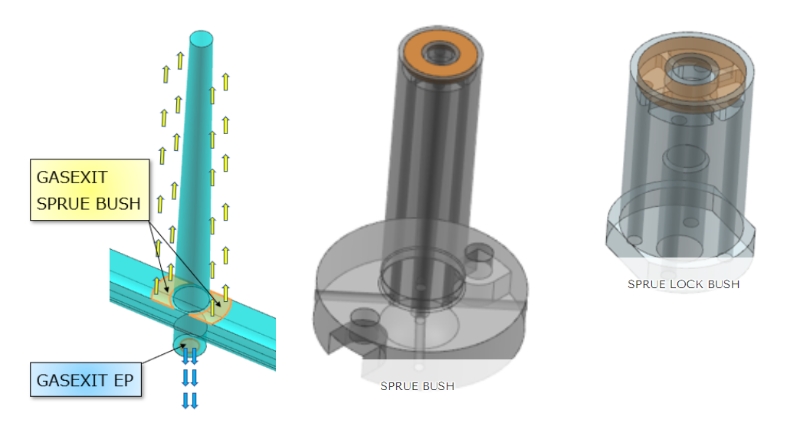

feature 01

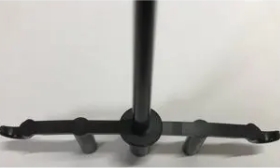

The gases removal effect improves when used in combination with GASEXIT EP

Even if the GASEXIT EP is installed at the cold slug, if the size is small, the gases flowing from the nozzle may not be able to be exhausted sufficiently with the GASEXIT EP alone.

However, by using GASEXIT BUSH together, even if the cold slug size is small, the gases can be discharged from the surface where the runner and bush contact, so it is possible to increase the Mold Venting volume.

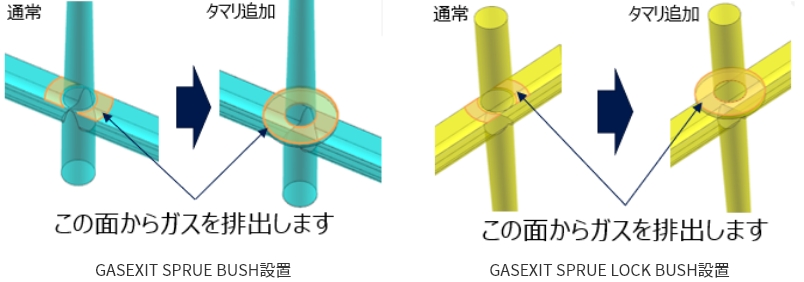

feature 02

Expanding the gas discharge surface by adding a puddle!

By reducing the length about 1 mm shorter than the existing bush, the sprue end is provided with a puddle.

Since it is possible to discharge the gases from the puddle side as well, the amount of discharge will be significantly increased.

(Roughly 6 times more ratio with the GAS EXIT EP)

feature 03

Available in the same standard dimensions as existing bushes

Since we will manufacture the product with the same size as the bush size that is currently in use, The customer does not have to modify anything, just replace it with the GASEXIT BUSH and you can immediately apply gassing countermeasures.

※Non-standard products can be manufactured if you specify us the dimensions.

Compatible with standard products of each company

Inquiries here regarding GASEXIT BUSH

The product 「GASEXIT BUSH」 can effectively reduce molding defects caused by gas and extend the maintenance cycle of the mold. If you have inquiries or would like to discuss further about GASEXIT BUSH, please feel free to contact us.

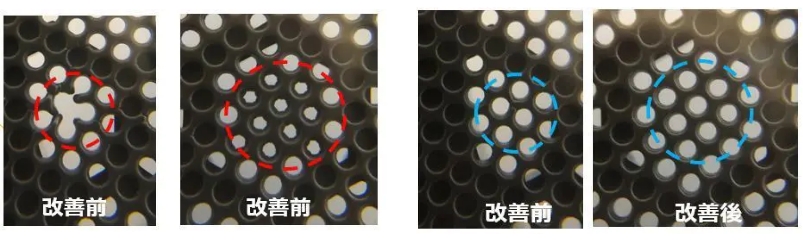

Example of a real usage of the GASEXIT BUSH

I want to solve a gas burn defect in a part in which an insert cannot be used.

Osaka Prefecture K Company

| Problem |

|

|---|---|

| Countermasure | Exchange sprue bush for the GASEXIT SPRUE BUSH |

| Results | Gas burn defect became 0% |

Solutions to burn marks in locations where cannot be made into inserts.

Thailand Company T

| Problem |

|

|---|---|

| Countermasure | Exchange sprue bush & sprue lock bush with GASEXIT SPRUE BUSH & GASEXIT SPRUE LOCK BUSH. |

| Results | Burn mark disappeared without mold maintenance. |

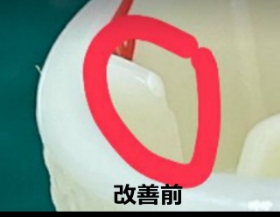

Solving short shot and flash without mold modification.

Japan Company N

| Problem |

|

|---|---|

| Countermasure |

|

| Results | Achieved defect-free molding conditions without short shot or flash. |

Inquiries here regarding GASEXIT BUSH

The product 「GASEXIT BUSH」 can effectively reduce molding defects caused by gas and extend the maintenance cycle of the mold. If you have inquiries or would like to discuss further about GASEXIT BUSH, please feel free to contact us.

Contact

Use the web form for inquiries or quotations.

Please referred to the frequent Q&A before request your inquiries.