- ホーム

- HOME

- Products Information

- GASEXIT EP

GASEXIT EP

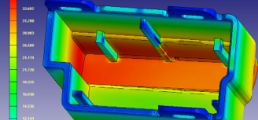

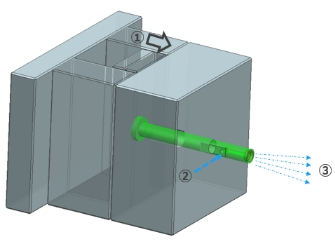

Gas venting image by replacing existing ejector pin.

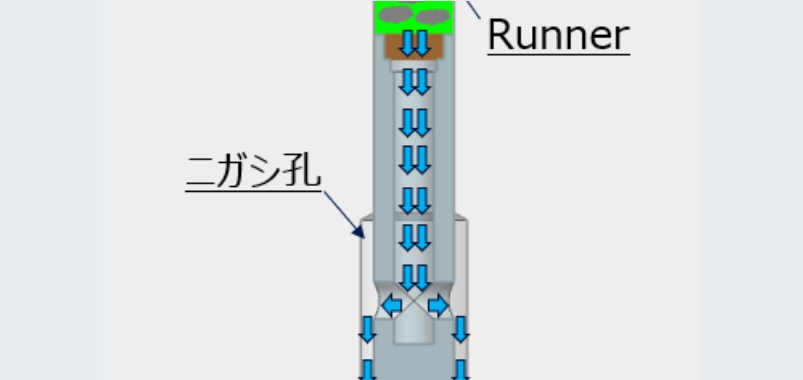

GASEXIT EP is an ejector pin that discharges gas from the realesing part of the ejector pin hole normally machined.

It is a product that can be easily used as a Mold Venting measure because it only has to be replaced in stead of the existing ejector pin.

It can also be installed on the cold slug part where injection pressure is high.

Gas venting image

Gas venting image clip

GASEXIT EP features

feature 01

Mold Venting volume increases more than 4 times!

Since the gap on the outer circumference of a normal ejector pin is about 0.01 mm, almost no gas can be released.

Simply replace the existing ejector pin with the GASEXIT EP and the gas will escape from the ejector pin realese part.

The area from which gases escape is more than 4 times higher than that of a normal ejector pin.

feature 02

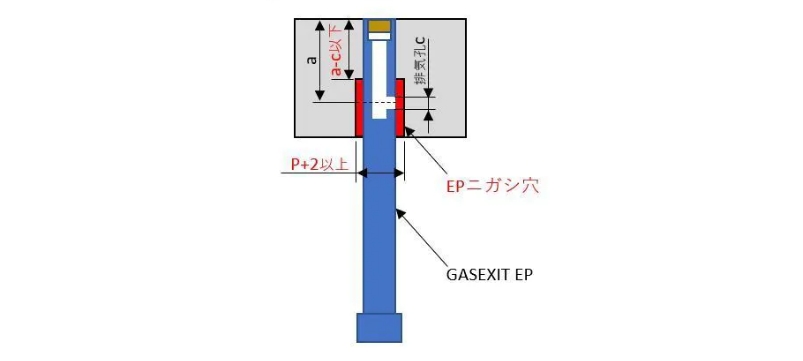

Possible for maintenance even attached with injection machine

The exhaust vents can be positioned close to the parting line, allowing them to be visible from the P/L when the ejector pins are extended. In this state, can easily blow a parts cleaner through the exhaust vents, facilitating the cleaning of porous areas and enabling easy confirmation of any clogging. This allows for maintenance to be carried out without removing the mold, providing a convenient and efficient solution.

feature 03

We can handle from precision molds to large molds

We have a minimum size of Φ2 and a maximum size of Φ16.

There are two types of steel, SKD61 + nitriding treatment and SKH51.

It is also possible to add machining to prevent brim rotation as well as tap machining.

| Diameter | Length |

|---|---|

| Φ2~Φ16 | 50≦L≦1000m |

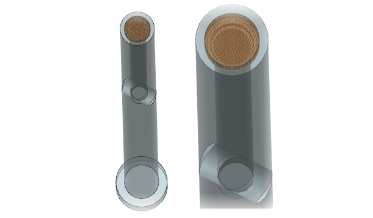

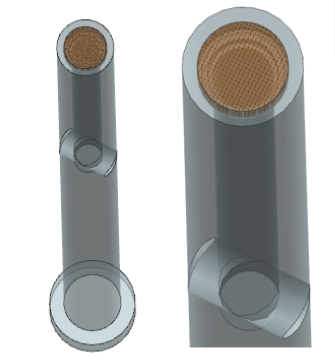

feature 04

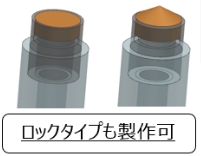

Lock type for holding the runner can also be manufactured

When using the GASEXIT EP for the ejector pin that currently holds the runner using the Z pin, we recommend the cylindrical lock type.

※Z pin can also be manufactured, but the gas discharge surface will be reduced

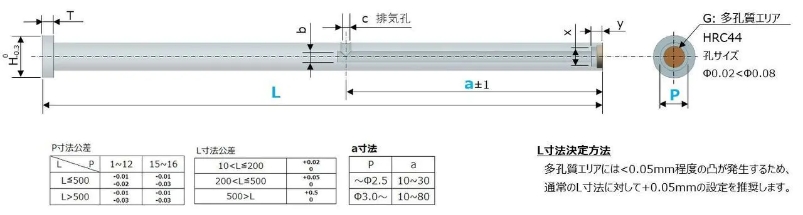

GASEXIT EP specifications

Points to keep in mind at the depth on the insert side of EP venting hole.

Inquiries here regarding GASEXIT EP

The product 「GASEXIT EP」 can effectively reduce molding defects caused by gas and extend the maintenance cycle of the mold. If you have inquiries or would like to discuss further about GASEXIT EP, please feel free to contact us.

Example of a real usage of GASEXIT EP

I want to improve the gas burn in the air trap part and the final filling part.

Thailand K Company

| Problem |

|

|---|---|

| Countermasure | 7 GAS EXIT EPs were installed on the core side of the product side |

| Results |

|

Inquiries here regarding GASEXIT EP

The product 「GASEXIT EP」 can effectively reduce molding defects caused by gas and extend the maintenance cycle of the mold. If you have inquiries or would like to discuss further about GASEXIT EP, please feel free to contact us.

Contact

Use the web form for inquiries or quotations.

Please referred to the frequent Q&A before request your inquiries.