Products Information

Introduction of original product, the gas venting insert「GASEXIT」, which effectively addresses molding defects in injection molding.

In addition to resolving molding issues, it also contributes to extending the maintenance cycle of molds and increasing the durability of molds in terms of shot count.

Facing These Challenges?

I want to solve molding defects caused by gases

Defects caused by trapped gas, such as discoloration, cloudiness, silver streaks, short shots, sink marks, and gas burns, highly effective gas venting parts where conventional methods fail.

I want a solution that does not clog the vent holes

Effective initially, but experience clogging after a few hundred to a few thousand shots, requiring frequent maintenance. Looking for products that do not clog the gas venting holes.

I want to extend the mold maintenance cycle and the number of durable shots

In order to prevent gas-related defects and mold corrosion, mold maintenance is regularly conducted. However, due to the high frequency of maintenance, aim to extend the maintenance cycle for cost reduction purposes.

[GASEXIT] The Solution for Injection Defects!

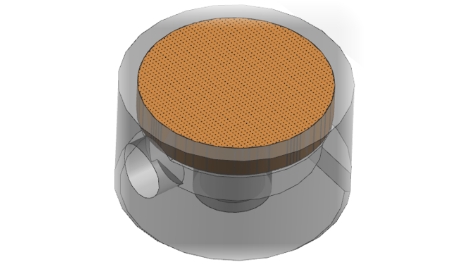

Difficult to clog Through vent structure implementation

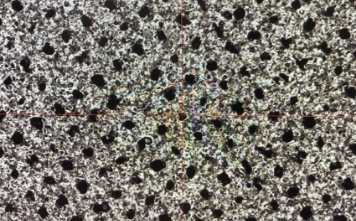

The pore size is Φ0.02 to Φ0.08 (pore pitch 0.2 mm), and it is very difficult for resin to flow into it because of it being a fine through hole that does not allow thinner to penetrate.

【Patent No. 6703689】

Moreover, since the gases can be exhausted almost completely, the optimum balance as a Mold Venting material for injection molding can be achieved.

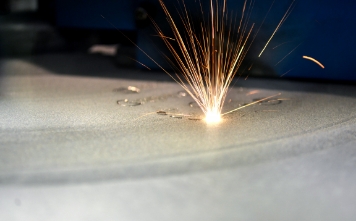

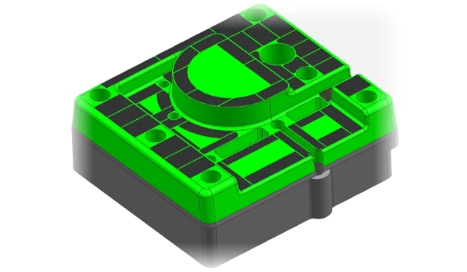

Metal 3D printer technology utilization

Since it is manufactured with a metallic 3D printer, it is possible to manufacture Mold Venting inserts of various shapes.

The surface hardness of the Mold Venting part is HRC44 after quenching, so it has excellent wear resistance.

Same day answer

We strive to “prompt PDCA” and “provide a proposal-based business with originality and ingenuity as well as a challenging spirit”, responding as fast as possible to all our customers.

We will do our best to solve our costumers problem as soon as possible.

Mold Venting parts made of fine through-hole porous material in order to solve molding defects.

The resin does not flow easily, and it has an optimal balance as a ventilation hole for passing gases.

If you have any questions, please feel free to contact us.

Original Porous Materials.

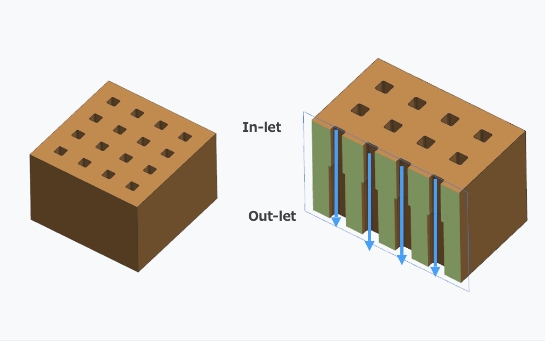

- Programmatically controlled pores allow for stable airflow.

- Easy for clog removal since through-holes.

- All pores allow airflow: through-holes.

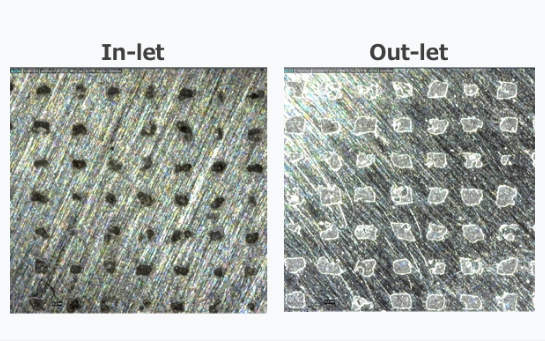

- The inlet has a small diameter: Φ0.05.

- The outlet has a larger diameter: Φ0.10.

- Thickness: 2mm.

This structure is suitable even with fine flowability resin materials.

Molding defects countermeasure parts「GASEXIT」

Product information

The Unique Gas Venting Product

Our Mold Venting parts are made of a fine through-hole porous material, so it has an optimal balance as a “hard to flow resin and allowing gases to pass through” vent hole.

Due to it’s effect, it is possible to improve molding defects (burn, clouding, Sliver streak, weld line, short shot, shrinkage, warpage, flash, etc.) caused by gases.

It also extends the mold maintenance cycle and improves the mold shot durability.

Since gases accumulated in the nozzle of the molding machine flowing into the product is the cause of defects, we have a lineup of products that prevent the gases from flowing into the product.

In addition to general-purpose resins, it can also be used for easily flow-able resins such as PBT (GF), PPS (GF), PA (GF).

Products Lineup

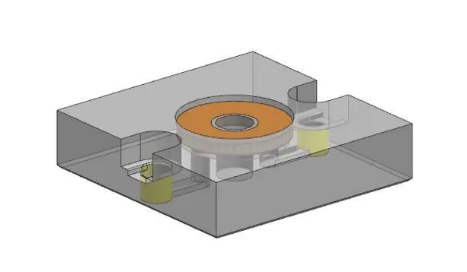

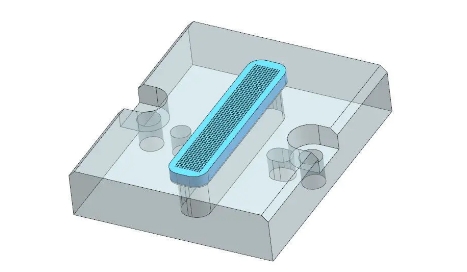

GASEXIT RUNNER

GASEXIT Runner is an insert that discharges gas laterally between the P/L surface and the plate. (Product patented)

This product was developed with the purpose of discharging the gases that flow in advance into the product part .

Given that it is only a Φ10~Φ15 machining on pockets and grooves, it is a product that can easily be used as a gases venting measure for existing dies.

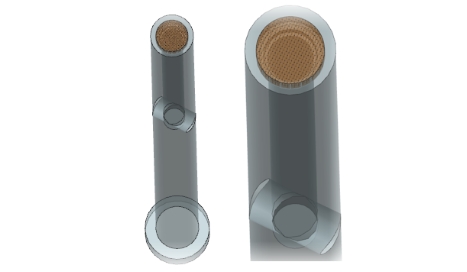

GASEXIT EP

It can be installed easily by simply replacing the ejector pins currently in use. By installing it in the cold slug section,as with GASEXIT RUNNER, you can remove the gases before they flow into the product section.

Of course, it can also be installed in the product part, so you can easily take measures to vent gases even from the product part.

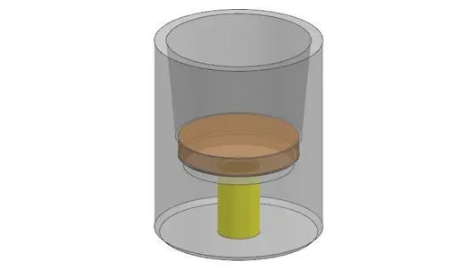

GASEXIT BUSH

It can be easily installed by simply replacing it with the sprue bush currently in use.

By providing a puddle in the end part of the sprue, it is possible to significantly improve the gas venting effect.

A sprue lock bush type is also available, it can be also installed on the cold slug side.

GASEXIT SPRUE BUSH JOINT

In cases of small size sprue bush, GASEXIT is recommended from the beginning in new molds.

Inexpensive way to efficiently exhausting a large volume of gas within small space.

GASEXIT SLUGWELL PIN

Enables gas extraction over a wide range through the use of a cold slug well. It allows for the efficient exhaust of a large volume of gas that accumulates at the nozzle tip during the injection initial stage, especially during the metering process.

GASEXIT CUSTOM

Please consider this option when you cannot install GASEXIT in the runner section and cold slug section or you want to improve if further.

Since it can be manufactured according to the insert shape of each product, it is possible to vent gases in a wide range.

3D curved and seamless gases venting inserts can be manufactured.

Suction Plate (heat & wear-resistant)

Porous suction plate is specifically designed for applications that require heat and wear resistance. It provides reliable vacuum gripping for various workpieces.

The position and size of the holes can be customized according to specific requirements.

「GASEXIT」Applications

The video on the right shows a state where air is being blown from the exhaust hole side and a thinner is being applied to the GAS EXIT surface.

- At the time of actual molding, gas is discharged from the GAS EXIT surface (the surface through which the resin passes = the surface from which the bubbles in the movie appear) to the exhaust hole side.

- It has a fine through-hole structure that does not allow thinner to penetrate.

This way, GASEXIT is capable of passing a large amount of gases, with a fine through-hole structure that does not allow thinner to penetrate, Since it has a structure that does not easily cause clogging due to resin flow during injection, it is effective as a Mold Venting measure during molding.

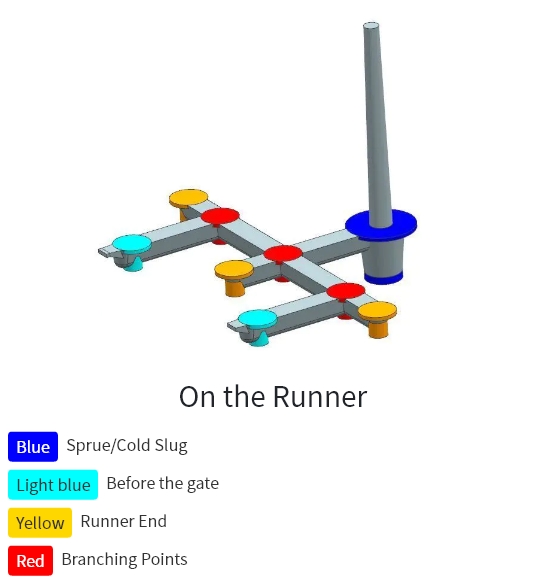

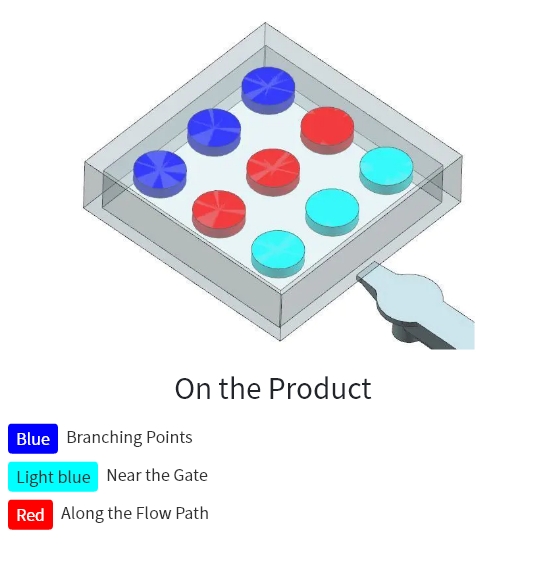

[GASEXIT] Where to Install

GASEXIT is not effective when installed in areas where resin can easily flow through since gas tend to flow the same.

GASEXIT is recommended to place in areas where gas tend to compress such as following.

[GASEXIT] How to Select

Please feel free to contact us when selecting the appropriate GASEXIT type. The best cost-effectiveness recommendations will be offered.

| Malfunction Modes | R | EP | B | C |

|---|---|---|---|---|

| Maintenance Cycle | ○ | ○ | ◎ | ○ |

| Silver Streaks | ○ | ○ | ◎ | ◎ |

| Burn Mark | △ | ○ | ◎ | ◎ |

| Short Shots | △ | ○ | ◎ | ◎ |

| Flash | △ | △ | ◎ | ◎ |

| Sink Marks | △ | △ | ◎ | ◎ |

※R: Runner pin type

※EP: Ejector pin type

※B: Sprue bush type, sprue lock bush type, runner lock bush type

※C: Custom type

Frequent Questions of 「GASEXIT」

Frequently asked questions regarding gas venting component 「GASEXIT」are here.

Please feel free to contact us for further assistance.

Contact

Use the web form for inquiries or quotations.

Please referred to the frequent Q&A before request your inquiries.