Business details

KOEI TOOL specializes in mold design, manufacturing, sales, and production of degassing parts.

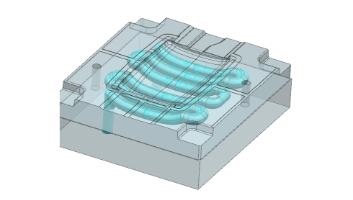

Designing and fabricating cooling inserts using metal 3D printers. Here are overviews of the company's business.

Localize Mold Procurement in Asia

Providing mold manufacturing and maintenance services at our six factories in Japan and Asia. Rich experience in leveraging polishing techniques to manufacture exterior parts and design components.

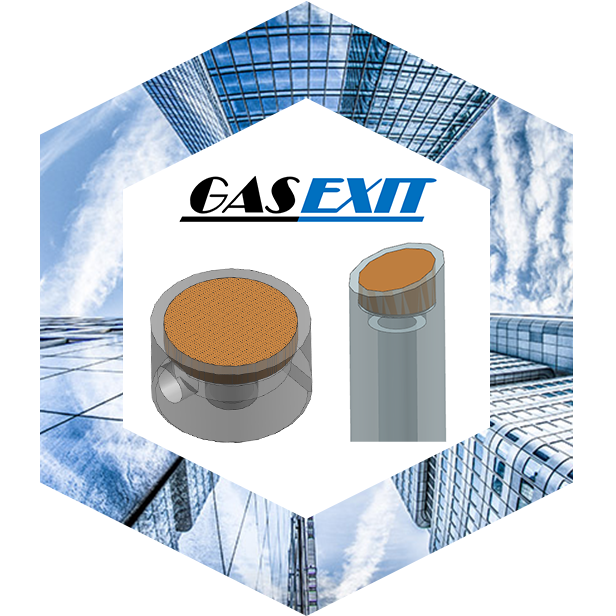

![Solution for Injection Defects [GASEXIT]](/dcms_media/image/tp-business-img02.jpg)

Solution for Injection Defects [GASEXIT]

Offering gas venting parts, 「GASEXIT」 (patented), to mitigate molding defects caused by gas. Our product lineup includes a variety of standard shapes to meet diverse requirements.

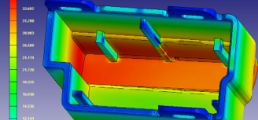

Manufacturing Services for Metal 3D Printing

Possession of two high-precision 3D metal printers. End-to-end solutions from modeling analysis to the actual printing of 3D cooling inserts.

Product information

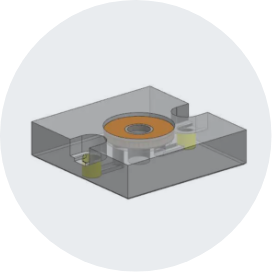

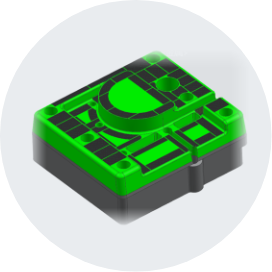

GASEXIT RUNNER

End of the runner type gas venting part. It can be easily installed by adding pockets onto the existing mold.

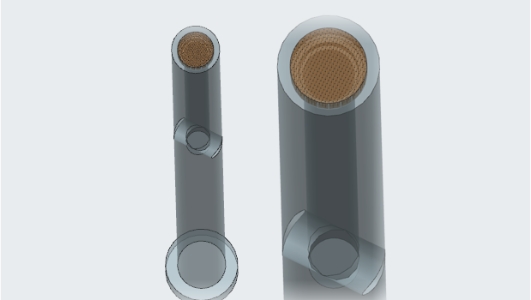

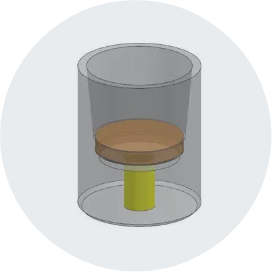

GASEXIT EP

Ejector pin type gas venting part. It can be easily installed by replacing the existing ejector pin.

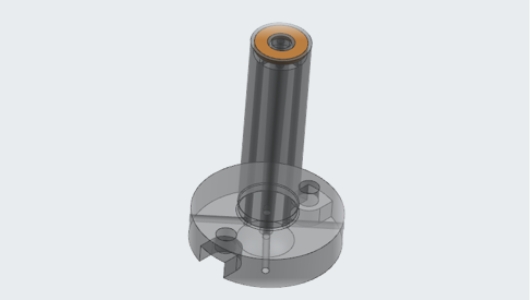

GASEXIT BUSH

Sprue end type gas venting part. It can be easily installed by replacing the existing sprue bush.

GASEXIT SPRUE BUSH JOINT

Joint component for cases where the size of sprue bush is small. Ensures venting area even in limited space.

GASEXIT SLUGWELL PIN

Slug well pin type gas venting part. Enables extensive gas venting in the cold slug well area.

GASEXIT CUSTOM

Custom design services for gas venting inserts. Tailored inserts to the specific shape of each product for extensive gas venting possibilities.

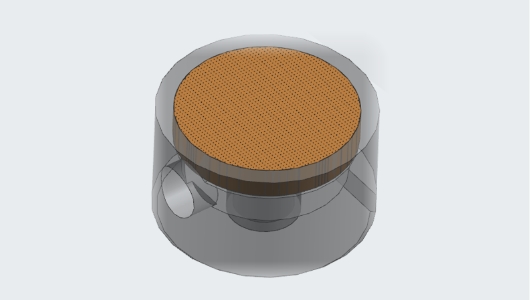

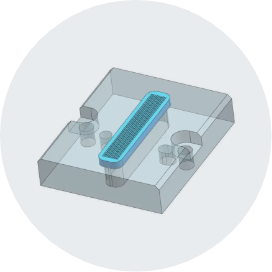

Suction plate (heat/wear resistant)

Porous suction plate designed with excellent heat and wear resistance. Customize pore size and position.

About us

Our Strengths

Leveraging the design and production capabilities of six factories in Osaka and Asia. Utilizing metal 3D printers with unique gas venting parts to manufacture custom-shaped components.

Equipment Information

Manufacturing for injection machines up to 350-ton class. Possess high-precision metal 3D printers.

Basic knowledge

News

Contact

Use the web form for inquiries or quotations.

Please referred to the frequent Q&A before request your inquiries.