Metal 3D printing has been gaining attention in recent years as a new technology that expands the possibilities of metal processing. This article provides an overview of metal 3D printing, including its principles of fabrication, benefits, drawbacks, and suitable applications, aimed at those considering the utilization of metal 3D printing technology.

Introduction to Metal 3D Printing:

Metal 3D printing refers to the process of additive manufacturing where metal materials are layered and built up according to the design data. It enables the fabrication of intricate and complex metal shapes that are challenging to produce using conventional machining metal processing methods.

Common Types of Metal 3D Printing Methods:

There are various types of metal 3D printing technologies available. In this section, we will introduce two of the most common methods.

Powder Bed Fusion Method:

The most widely used method in metal 3D printing is the powder bed fusion method. In this method, a high-energy heat source such as a laser or an electron beam is used to irradiate metal powder, melting and solidifying it to build up the layers. Our company adopts the powder bed fusion method.

The advantages of the powder bed fusion method are its high reproducibility and dimensional accuracy. However, one of the drawbacks is that it takes time to build the desired shape as the process involves layer-by-layer deposition and melting of metal powder.

Directed Energy Deposition (DED) Method:

Directed Energy Deposition (DED) is a method of additive manufacturing that involves simultaneous jetting of metal powder and laser irradiation from a nozzle to melt and solidify the metal powder in a layered manner. The main advantage of DED is its faster build time compared to the powder bed method. Unlike the powder bed method, DED does not require the removal of metal powder. It allows for the deposition of different metal materials on the surface, enabling features such as cladding and coating. However, a disadvantage of DED is that its dimensional accuracy is not as high as that of the powder bed method.

Advantages of Metal 3D Printing

Three benefits of using metal 3D printing

Advantage 1:

High Shape Reproducibility and Increased Design Freedom

Metal 3D printing enables the fabrication of intricate and complex shapes that are challenging to produce using traditional metal manufacturing methods. It allows for the realization of fine and intricate shapes that cannot be achieved with cutting processes or are difficult to remove from molds.

Advantage 2:

Prototyping with Short Lead Times

Metal 3D printing allows for the rapid production of prototype parts within a short timeframe. By integrating multiple components into a single part using metal 3D printing, the number of individual parts and manufacturing processes can be reduced, leading to cost savings. With the availability of design data and suitable materials, new parts can be fabricated quickly, enabling faster product development cycles.

Advantage 3:

Simultaneous Printing of Multiple Varieties

Metal 3D printing allows for the simultaneous fabrication of different product varieties. Depending on the shapes and materials of the objects being produced, complex parts can be printed in larger quantities at once, resulting in cost savings compared to purchasing individual parts. This capability enables efficient production of diverse components and supports customized manufacturing requirements.

Disadvantages of Metal 3D Printing

There are 3 disadvantages as well

Disadvantage 1:

Limitation in printing size

Metal 3D printers, despite offering high design flexibility, have limitations in printing size. The size of the objects that can be printed is restricted by the dimensions of the printer's build platform. Additionally, depending on the printing method, there may be a compromise in accuracy, requiring post-processing to achieve the desired specifications.

Disadvantage 2:

Not suitable for mass production

Depending on the size of the object being printed, metal 3D printers are not well-suited for mass production. As mentioned in Disadvantage 1, the build size limitations of the printer's build platform prevent simultaneous printing of large objects. This limitation makes it challenging to achieve high-volume production efficiently using metal 3D printing technology.

Disadvantage 3:

Difficult to achieve cost-effectiveness

The initial cost of metal 3D printers is typically higher compared to conventional machining equipment. Additionally, the cost of materials used in metal 3D printing is generally more expensive than traditional steel materials. Metal 3D printers also consume more power than machining equipment. These factors can make it challenging to achieve cost-effectiveness, especially for certain applications or production volumes.

What is metal 3D printing suitable for?

What applications is metal 3D printing well-suited for? In this section, we will provide a detailed introduction.

(1)Manufacturing complex-shaped metal parts

Metal 3D printing is well-suited for the manufacturing of complex-shaped metal parts. It enables the production of intricate shapes that are difficult to fabricate using conventional metal processing methods, such as shapes that cannot be accessed by cutting tools or shapes that are challenging to extract from molds.

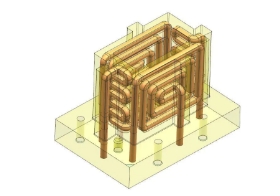

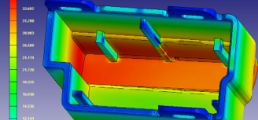

(2)Manufacturing molds and manufacturing tools

Metal 3D printing allows for the production of molds and manufacturing tools, enabling the fabrication of mass-produced parts and the supply of discontinued products. Even in the event of damage, it is possible to manufacture new molds or tools as long as the 3D model design data of the product is available. Additionally, the use of design data makes it relatively easy to make improvements or modifications to the products.

(3)Reduce of component weight

Metal 3D printing allows for the integration of multiple parts into a single component, leading to lightweighting. By using the necessary amount of material only where it is required, weight reduction can be achieved. Additionally, by adjusting the thickness and density, it becomes possible to not only achieve lightweighting but also ensure the strength of the component.

(4)Small batch production

Metal 3D printing enables manufacturing from a single unit and is well-suited for small batch production. It is ideal for on-demand production of customized products, manufacturing discontinued parts, and rapid prototyping. The ability to produce small quantities efficiently and cost-effectively makes it a valuable tool for various industries.

Small batch production

Metal 3D printing enables manufacturing from a single unit; making it suitable for on-demand production, discontinued parts, and rapid prototyping.

Summary:

Metal 3D printing offers benefits such as high shape reproducibility and improved work efficiency, but it also comes with certain drawbacks due to its evolving nature. It is important to consider the specific characteristics of metal 3D printing, including its various fabrication methods, advantages, and disadvantages, to determine if it is suitable for your metal processing needs. The company specializes in providing 3D printing services for metal cooling molds. If you are looking for molds with high design aesthetics or molds equipped with 3D cooling inserts, please feel free to contact us for further assistance.

Metal 3D printing service

KOEI TOOL also offers manufacturing services utilizing metal 3D printing for specialized components that require conformal cooling inserts or have complex shapes that are difficult to produce using traditional machining methods.

Inquiry here

Please contact us for any inquiries regarding KOEI TOOL's technology and services, including requests for quotations and delivery times.