FAQ

Compilation of the most frequent asked Q & A regarding plastic injection mold manufacturing, defect prevention, gas venting inserts「GASEXIT」、and metal 3D printer modeling.

Regarding oversea support

There are many facilities, which one should I contact?

First, through the "Contact Us" on this website.

Once we receive your inquiry, a Japanese representative will promptly get back to you to discuss your needs and requests.

Can I contact Indonesian facility directly?

Yes, you may contact directly via phone call etc.

What oversea support service can you provide?

Turnkey support from quotation, manufacturing, sampling and afterword maintenance in case of new molds.

Do I need to visit the local site for mold discussions?

All sites are capable to conduct web meetings via platforms such as Zoom or Teams.

Therefore, we can hold meetings online regardless of the customer's location.

Is it possible to visit oversea facilities?

Visiting our overseas factories is indeed possible.

Basically, the visits would involve meeting at the factory site and concluding the tour at the same place.

However, we can also provide assistance from the nearest airport to the factory location for your convenience.

Is it possible to have meetings between local staffs?

Meetings with local staff members are possible at all our group locations.

We have received positive feedback from customers who prefer to have meetings conducted by local staff members at the respective locations.

Is it possible to conduct meetings in Japanese?

We have both Japanese or Japanese-speaking staff members on each location. Therefore, Japanese-language meetings can also be conducted on-site.

Is it less expensive to make molds oversea relative to Japan?

The cost of mold production can be 10-20% cheaper in overseas locations, but additional logistics costs may offset the price advantage to a significant extent. Moreover, the lead time is increased by the duration of transportation. If the molds are intended for use in Japan, such as for mass production in Japan, it would be smoother to place the order with our Japanese subsidiary.

Is the precision of the machines used in overseas factories reliable?

The major machining equipment such as machining centers, EDM machines, and wire EDM machines used across our group are either made in Japan or sourced from Japanese manufacturers. Therefore, there are no issues with precision. You can refer to the equipment list for the number of machines we have.

Is a local maintenance contract necessary for mold maintenance during mass production?

We will continue to provide paid or complimentary maintenance services for new molds that you have ordered without requiring any special contracts.

If a mold is initially manufactured in Japan by KOEI TOOL and then transferred to Thailand for mass production, do mold modifications or repairs in Thailand would typically incur additional charges?

If the modifications or repairs align with the standard free-of-charge services provided by KOEI TOOL in Japan, we will continue to offer them free of charge even after the mold transfer to Thailand. However, it is essential to notify us of the intention to transfer the mold at the beginning of its construction. As for any chargeable services, they would be provided at the regular quotation price of the local factory in Thailand.

Do you also accept maintenance-only jobs at Japanese and overseas factories?

We also accept maintenance of molds that were not produced by our group. However, we generally require the provision of 3D data. The price for maintenance tends to be higher compared to when the maintenance is carried out by the original mold manufacturer. Additionally, if the mold dimensions fall within the specified tolerances, is considering responsibility fulfilled. However, if the customer is not satisfied and further modifications are requested, the usual fees will apply.

Is it possible for KOEI TOOL to handle mold manufacturing and maintenance in countries where it does not have factories?

If it is in Southeast Asia, we can provide support from nearby factories. Currently, we are already providing mold manufacturing and maintenance services to customers in Vietnam from our Singapore factory.

If I plan to transfer the molds from Japan to Thailand for mass production, can KOEI TOOL assist in shipping the molds from Japan to Thailand?

We apologize for the inconvenience. The export of molds would need to be arranged by the customer thus the costs associated with the shipment.

If I plan for the mass production in Japan, it is possible to place the order for the mold with the Thai factory and make the payment through the Japanese factory?

We apologize for the inconvenience. Please arrange the payment directly to the Thai factory.

If I plan to export the molds, can you provide the certificate of origin or determination of eligibility?

We generally do not provide the certificates of origin. If you have such a request, please note that additional fees and processing time will be required. However, we can issue the determination of eligibility certificate within three days.

Why do you have many oversea facilities?

To meet your needs for stable mass production and prompt troubleshooting, KOEI TOOL Group has established local factories in Asia for efficient new mold production and maintenance. We will continue opening factories in the region to provide agile and efficient services.

Inquiry and quotation here

Please contact us via website or phone call for inquiries and quotations.

Regarding molds

How large of a mold can you produce?

We can produce molds up to the size suitable for 350-ton class injection molding machines.

Can you perform mold feasibility verification?

We will verify the feasibility of all molds.

In case of any non-feasible aspects, we will request modifications to the product design.

What surface finishes are available for the molds?

We can accommodate surface finishes such as piano black, painting, and resin plating with a polishing level of approximately #10000.

Can you also manufacture prototype molds?

Yes, we can.

Do you support hot runner systems?

Yes, we can also accommodate open gates, valve gates, mini runners, and other types of gating systems. We work in collaboration with hot runner manufacturers to provide the necessary support.

Do you support texture processing?

Yes, we can accommodate various textures such as matte, leather grain, and laser engraving textures. We work in collaboration with texture suppliers to provide the necessary support.

What kind of molding machines do you have?

Osaka factory has one molding machine each with capacities of 100 tons, 260 tons, and 350 tons. Currently, we do not have any double-color molding machines, but we can arrange for them through our cooperative factories.

Inquiry and quotation here

Please contact us via website or phone call for inquiries and quotations.

Regarding molding defect prevention component 「GASEXIT」

What is the steel material for porous parts?

It’s maraging steel.

What is the hardness of porous parts?

Approximately HRC44-50. It is possible to achieve a surface hardness of approximately HRC70 through nitriding.

Can it be used with resin containing glass fiber?

If the resin contains 20% or more glass fiber, we recommend opting for the nitriding treatment. With the nitriding treatment, you can use it without any issues.

What is the expected service life or shot count?

The wear condition can vary depending on the type of resin, molding conditions, and installation environment. However, there have been successful cases where PC resin molds have been used without issues for over 500,000 shots. Additionally, with the implementation of nitriding treatment, there have been successful cases of using PA resin with 50% glass fiber content for over 500,000 shots without problems.

What is the maximum injection pressure it can withstand?

Depending on the installation location, it can withstand injection pressures of approximately 130 MPa to 150 MPa. For injection pressures exceeding 130 MPa to 150 MPa, it is possible to improve the load-bearing capacity up to approximately 200 MPa by increasing the thickness of the porous area as an optional feature.

Doesn't corrosion occur due to gas exposure?

As long as clogging does not occur, the gases that can cause corrosion are expelled, so corrosion due to gas exposure does not occur. There are successful cases of using even highly corrosive gases such as PVC without any issues.

Does mold deposit (gasyani) adhere?

The mechanism of mold deposit formation involves gas compression→liquefaction→solidification. However, the surface has small micropores (Φ0.05) while the internal and bottom surfaces have larger pores (Φ0.1~Φ0.3), making it difficult for gas to be compressed. As a result, the adherence of mold deposit is less likely to occur.

Can additional processing be done on the porous part?

If the depth of the surface is 0.1mm or less, it is possible to perform additional processing on the surface. However, if the processing goes deeper, it will enter a layer with larger pores (Φ0.1), which can cause clogging due to resin flow.

Is EDM the only method for additional processing of porous areas?

Yes, using methods other than EDM may cause clogging due to residue. Expertise in both EDM and the cleaning process are necessary after machining. If additional processing is required, please consult with us for further assistance.

Can dimensions that are not listed in the catalog be manufactured?

Yes, if you provide us with drawings or dimensions, we can proceed with the production.

Can the size of the porous hole be changed?

The standard size for the porous hole is Φ0.05±0.03. However, it is possible to accommodate larger pore sizes such as Φ0.10±0.03 as an optional feature. Additionally, it is also possible to produce a size of Φ0.03±0.03 as an option. However, it should be noted that this smaller size may result in more clogged pores, reducing the airflow capacity to approximately 50% compared to the standard size.

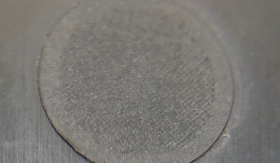

Is the porous shape printed to the product section?

Yes, the transfer of the porous section to the product section does occur. The extent of transfer may vary depending on factors such as resin type, molding conditions, and installation location. However, it typically results in a textured pattern with surface irregularities of approximately 0.01 to 0.05mm, similar to a pearlescent finish.

Is it possible to use any type of resin without clogging?

The situation may vary depending on the resin type, molding conditions, and installation location. However, LCP resin, PU resin, and PPS resin have a tendency to be prone to clogging. It is worth noting that there have been cases where even thermosetting resins have been successfully used. If you have concerns about clogging, we can suggest installation methods that are less prone to clogging. Please feel free to consult with us for further assistance.

Is it possible to provide samples for evaluation?

We can provide evaluation samples if you agree to disclose detailed information about the issue and the intended installation location. If our company determines that we can achieve improvement, we can offer the samples under a success-based compensation arrangement for a three-month evaluation period.

How many GASEXIT units need to be installed to address gas venting?

The required number of GASEXIT units for effective gas venting will vary based on resin type, molding conditions, installation location, and gas generation per shot weight. It is recommended to start with larger-sized GASEXIT units and gradually increase the number while monitoring the situation.

Will the weld line improve?

It is not possible to eliminate the weld line. However, if the appearance defect in the weld line is caused by gas-related issues, improvement can be expected.

Can void defects be improved?

There is a high possibility that installing GASEXIT in areas where voids occur can lead to improvement.

Can silver streak defects be improved?

There have been numerous cases where silver streak defects have been improved.

Is it possible to modify the shape at the tip of GASEXIT EP?

Yes, it is possible to modify the shape of GASEXIT EP, including 3D shapes. We can also accommodate the production of Z-pins.

What is the approximate price range for GASEXIT CUSTOM?

The price of GASEXIT CUSTOM is typically 1.5 to 2.0 times higher than the standard version.

Is daily maintenance necessary?

Yes, daily cleaning is recommended. We suggest cleaning the porous section using a parts cleaner as the preferred cleaning method.

Is periodic maintenance required?

Yes, periodic maintenance is recommended. The cleaning frequency may vary depending on the usage environment, but we recommend cleaning (using ultrasonic cleaning) every 30,000 to 50,000 shots.

Is it possible to restore functionality in case of clogging?

Yes, it is possible to remove clogging by using ultrasonic cleaning to eliminate the clogged substances. If ultrasonic cleaning is not effective, heating the component in an oven at around 450°C can be used to remove the clogged materials.

Do you provide maintenance services?

Yes, we provide maintenance services. Free maintenance within 3 months after delivery, but after that period, maintenance will be subject to charges.

Inquiry and quotation here

Please contact us via website or phone call for inquiries and quotations.

Contact

Use the web form for inquiries or quotations.

Please referred to the frequent Q&A before request your inquiries.