- ホーム

- HOME

- Business Details

- Mold Manufacturing

Mold Manufacturing

Introduction KOEI TOOL's mold manufacturing capabilities. Specialist in producing plastic injection molds for machines up to 350 tons.

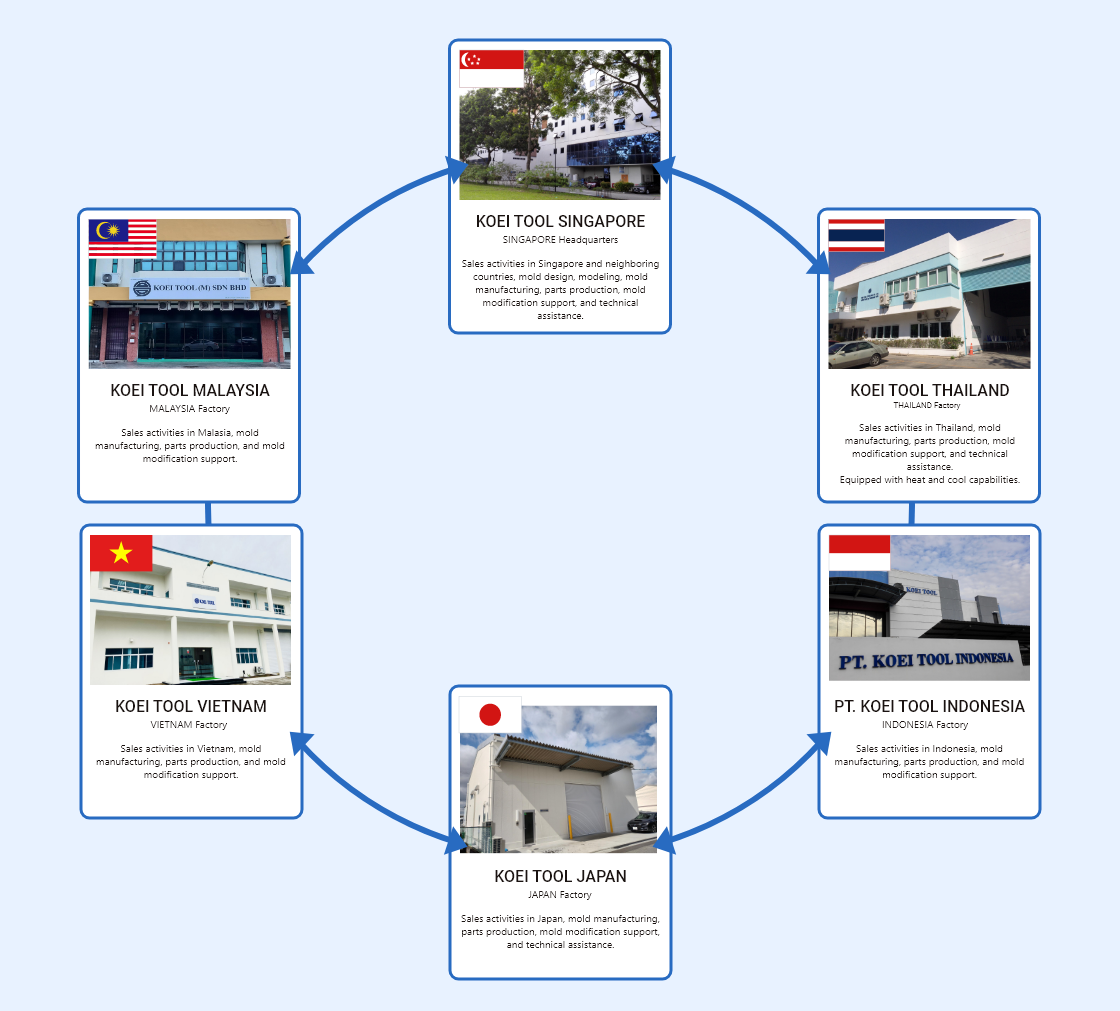

Leveraging the strengths of six group factories enables local sourcing and maintenance services.

Full utilization of KOEI TOOL's six group facilities manufacturing system.

Manufacturing of plastic injection molds.

Factories in Osaka, Singapore, Thailand, Indonesia, Malaysia, and Vietnam, leveraging a cross-country manufacturing network and providing new mold construction (mold quotation, design concept discussions, production, trial, and maintenance). Distributing design and manufacturing tasks across factories enables the handling of many new mold constructions that a single facility cannot accommodate—tracked records of maintenance and upkeep services at local molding facilities.

Furthermore, the production of high-quality molds, particularly for aesthetically designed resin parts, as well as double-color molds and heat-and-cool molds that require precise engineering.

Areas of expertise

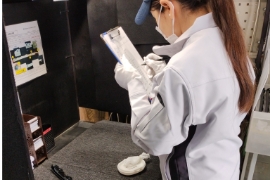

Polishing

Highly advanced polishing skills specialized for molds of exterior parts. The polishing techniques have been applied to numerous products, showcasing the technical prowess. While machining processes may leave machining marks, skilled polishing ensures these marks are minimized. This is crucial in preventing molding defects. Moreover, manual polishing by skilled craftsmen is essential to achieve visually appealing exterior products.

Various tools and techniques are applied, such as diamond paste, sandpaper, felt, rotary tools, and ultrasonic equipment, to polish the metals manually. The polishing time can vary depending on the desired level of surface finish, with some parts requiring more than 10 hours of polishing for optimal results.

Heat & Cool injection system

Thailand's factory was introduced with exceptional heat and cool molding equipment, quickly evolving with the latest technology. Heat and cool molding is a technique where the mold is repeatedly heated and cooled during the injection of molten resin into the mold, resulting in improved surface quality of the molded products. This technology contributes to the production of high-precision molds.

Double-color molding

We are cultivating unique expertise in double-color metal fabrication—numerous tracked records in manufacturing buttons for automotive panels.

It implements a double-color molding machine that can combine two different materials by rotating the movable mold 180 degrees within a single molding cycle. Examples of successfully using this technique for molding products with durable hinges that can withstand folding and stretching, integrating rigid materials with waterproof gasket materials, and achieving integrated molding of materials with and without plating.

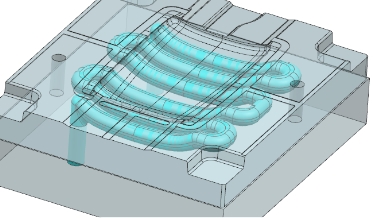

3D Cooling Insert

Possessing metal 3D printers enables manufacturing molds that require 3D cooling inserts. Even easily cracked materials such as SKD61 are now possible to utilize. 3D cooling inserts for die casting and other applications are also available.

Manufacturing Process

Design Concept Discussion

Discuss delivery schedule, mold structure, and feasibility, to ensure alignment with customers’ requirements.

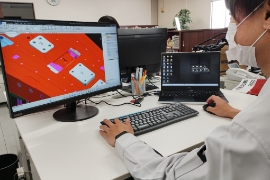

Product 3D Editing, Flow Analysis, and Modeling Data Processing.

Modeling the product and conduct flow analysis to examine any molding issues. Based on the results, develop mold concepts and conduct mold evaluations to provide customers with recommendations.

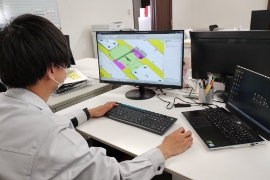

Mold Design

Designing mold with 3D CAD software.

Mold Manufacturing

High-performance machinery such as machining centers and EDM to perform precision cutting of steel. After the machining, apply assembly work for the molds with manual inspections under skillful eyes.

In-House Trial and Modification

In-house trial production to conduct quality checks of the molds.

Mold Shipment and Delivery

Deliver the molds to specified locations with experienced logistics service.

Contact

Use the web form for inquiries or quotations.

Please referred to the frequent Q&A before request your inquiries.