- ホーム

- HOME

- Products Information

- GASEXIT RUNNER

GASEXIT RUNNER

Easy to set up at runner end

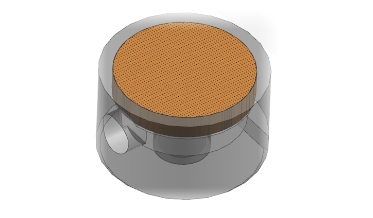

GASEXIT RUNNER is an insert that discharges gases laterally between the P/L surface and the plate.

【Patent No. 6664721】

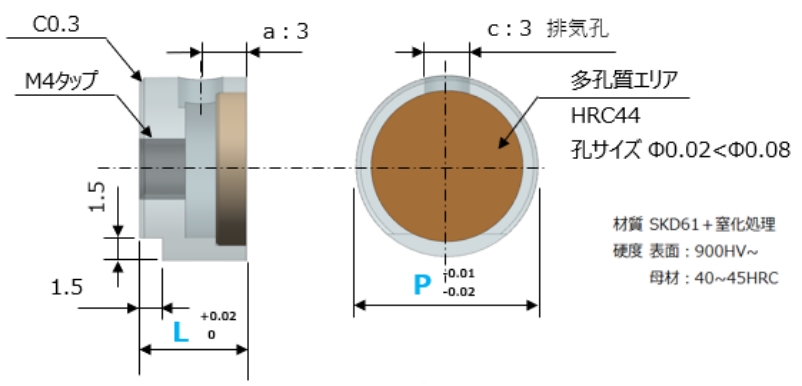

Given that it is only a Φ10~Φ15 machining on pockets and grooves, it is a low-cost, easy-to-use Mold Venting measure for existing dies.

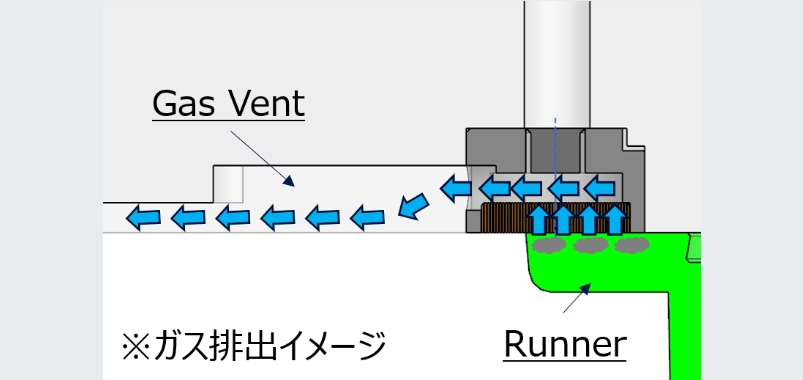

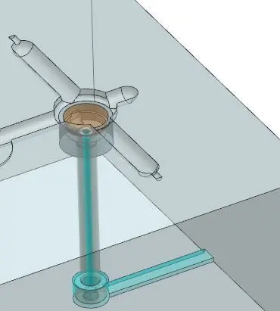

Gas venting image

It allows the gas to escape throughout the entire surface when installed in cold slug, improves gas venting effectiveness.

Gas venting image clip

GASEXIT RUNNER features

feature 01

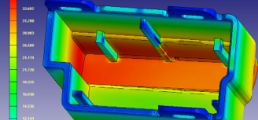

Gases venting are 15 to 20 times higher!

The gases vent machined in the normal runner end has a hollow dept of about 0.02 mm, so almost no gases can be released.

By installing the GASEXIT RUNNER will overlap the runner end, so gases will escape from the overlaped area.

The area through which gases escape is increased from 15 to 20 times than that of a normal gases vent.

feature 02

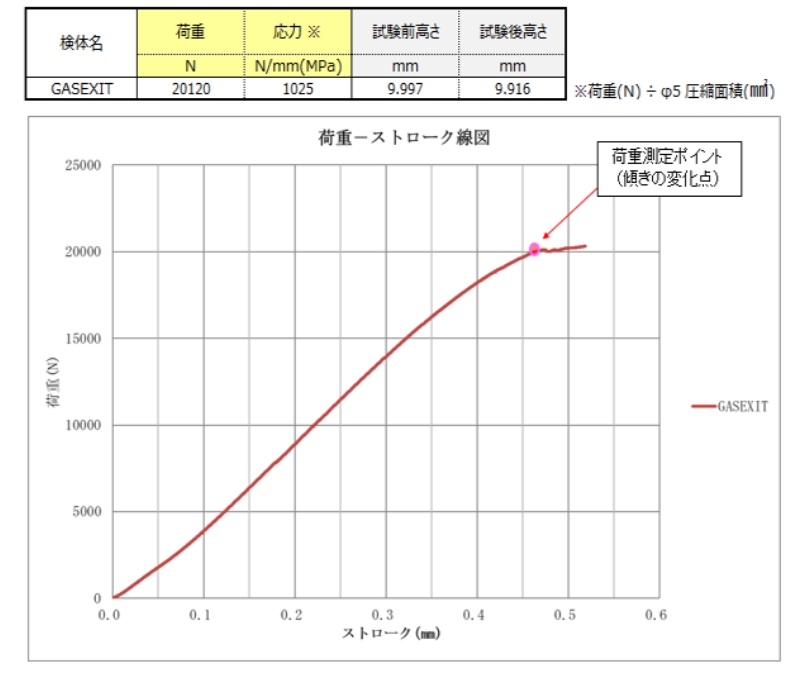

Withstand a 20,000N load

The result of a compression test using a GASEXIT RUNNERof Φ12 mm and a rod of Φ5 mm, has confirmed that it can withstand a load of 20,000 N .

Therefore, there is no concern about buckling due to resin pressure.

feature 03

Supports large molds

We have three sizes, Φ10, Φ12, and Φ15.

The Φ15 can be used for large molds with large runner sizes.

Since the minimum thickness is 7 mm, when adding GASEXIT RUNNER to a mold Which is already in mass production, the size is set so that it will not interfere with the mold temperature control water pipe.

| Diameter | Length | 備考 |

|---|---|---|

| Φ10 | L7mm | 通気孔 950個 |

| Φ12 | or | 通気孔1580個 |

| Φ15 | L10mm | 通気孔2800個 |

Inquiries regarding GASEXIT RUNNER, please contact us here.

Interested in the product「GASEXIT RUNNER」which reduces molding defects caused by gas and to extend the maintenance cycle of molds, please feel free to contact us for inquiries or consultations.

Installation method

Installation method

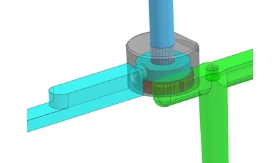

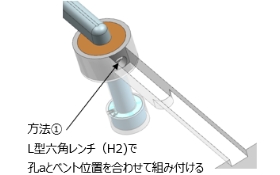

①Positioning using a Hex wrench

- Insert the L-shaped hex wrench (H2) into the exhaust port of the GAS EXIT RUNNER

- Align the direction of the hex wrench (exhaust port of the GASEXIT RUNNER) with the direction of the gas vent groove and insert it in the pocket

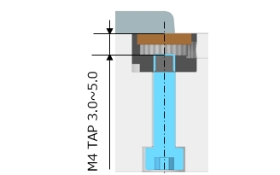

- Fixed with a M4 tap

※Not required if it has been press-fitted fixed

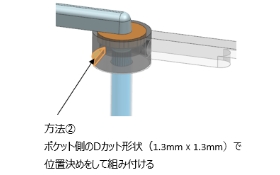

②Positioning method using D-cut shape

- A 1.3 mm x 1.3 mm D-cut shape that is perpendicular to the gas vent groove is machined on the mold base side.

- Align the D-cut direction on the GASEXIT RUNNER side with the D-cut shape on the mold base side and insert it into the pocket

- Fixed with a M4 tap

※Not required if it has been press-fitted fixed

Precautions

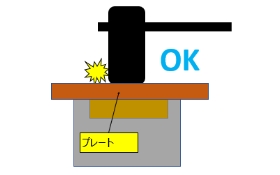

- If you hit the center of the GASEXIT RUNNER, it may be deformed, so if you hit it when inserting it, please pinch the plate.

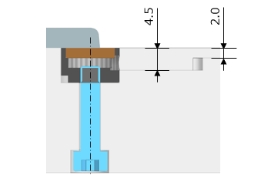

- Adjust the length of the tap so that the M4 tap does not hit the bottom of the GASEXIT exhaust side and the tip of the tap comes to a position of 3.0 mm to 5.0 mm from the surface.

Mold base side gas vent machining details

- Please machine the pocket according to the external shape and depth of the GAS EXIT RUNNER you purchased.

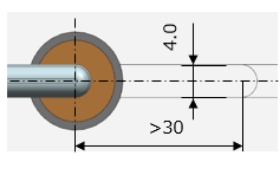

※The pocket should be machined so that the runner edge and the GASEXIT porous part overlap as much as possible. - Machine a gas vent groove with a depth of 4.5 mm x a width of 4.0 mm x a length of 30 mm or more

※When fixing the position with a D-cut shape, It is possible to have a groove length of 30 mm or less - Please machine the gas vent groove to a depth of 2.0 mm x a width of 4.0 mm to the outside of the mold base.

※If the groove depth is shallow, it may not be possible to exhaust gas sufficiently.

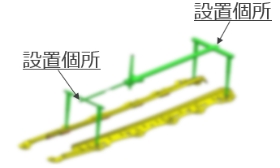

Cold Slug Setup Method

- The main insert can be secured using M4 bolts with holes. Additionally, a groove can be machined on the bottom surface of the main insert to provide an external connection.

Example of a real usage of GASEXIT RUNNER

Reduction of silver streak defects while also wanting to reduce maintenance frequency

Osaka Prefecture K Company

| Problem |

|

|---|---|

| Countermasure | Install 2 GAS EXIT RUNNER at the edge of the runner |

| Results |

|

Inquiries regarding GASEXIT RUNNER, please contact us here

Interested in the product「GASEXIT RUNNER」which reduces molding defects caused by gas and to extend the maintenance cycle of molds, please feel free to contact us for inquiries or consultations.

Contact

Use the web form for inquiries or quotations.

Please referred to the frequent Q&A before request your inquiries.