- ホーム

- HOME

- Products Information

- GASEXIT CUSTOM

GASEXIT CUSTOM

Tailored made to match the shape of the insert

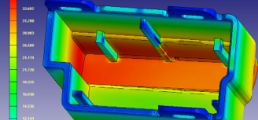

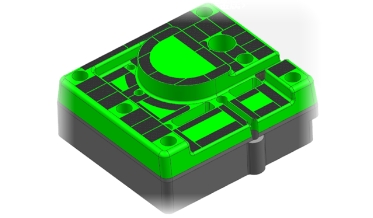

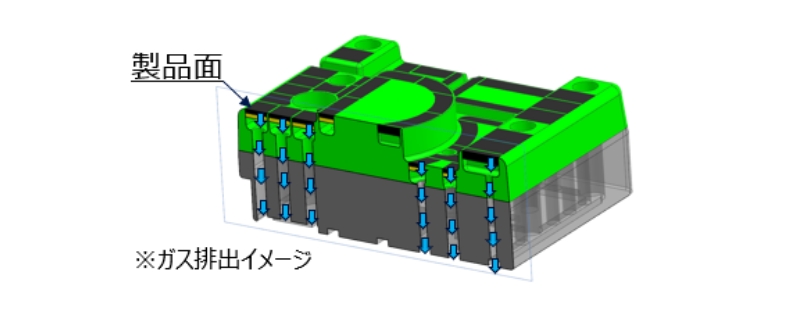

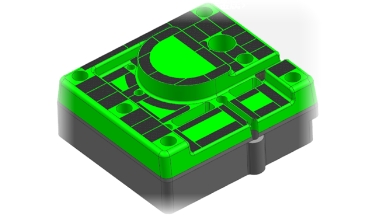

GASEXIT CUSTOM is an insert that discharges gases from the product side.

We recommend this when the gas problem cannot be solved even with the GASEXIT RUNNER/GASEXIT EP.

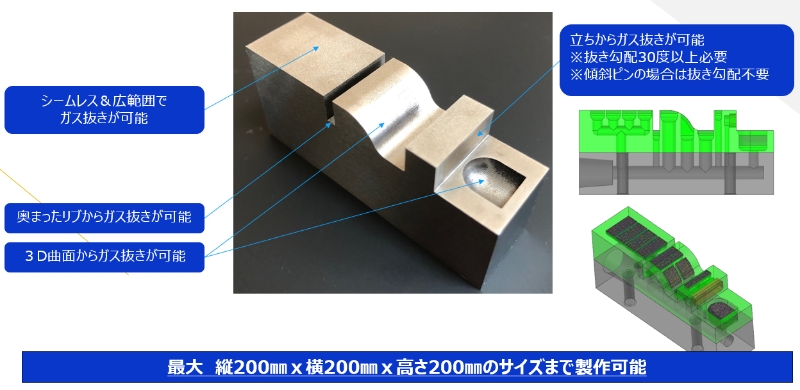

Since each product can be manufactured according to the insert shape, gases can be released from 3D curved surface, seamless in a wide range .

We will visit the customer and listen to the content of the problem, and we will propose as well design it all, so there is no need for troublesome considerations on the customer side.

※We can manufacture up to 200mmx200mmx200mm size.

Gas venting image

Enables degassing that was previously impossible

GASEXIT CUSTOM features

feature 01

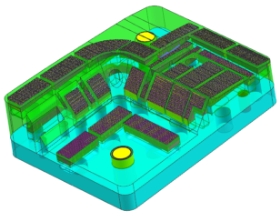

Even if the flow of resin changes, it is possible to reliabily discharge gases!

A normal degassing inserter degasses from the part line, but if the flow changes even a little, the position of the final filling part and others, will shift and it will be almost impossible to Degas.

Since the GASEXIT CUSTOM can set up a gas venting area over a wide area, gases can be vented without worrying about slight flow changes.

feature 02

No worries about uneven transfer to the cabity side

If you provide us with information on the defects content in molded products and mold data, we will take comand for everything from proposals to design as well as the GASEXIT CUSTOM production.

Confirmation with ABS resin (mirror finishing)

Confirmation with PP resin (texture finishing)

feature 03

We will take comand from proposal to mold modification

When the mold side is a mirror surface or a textured surface, unevenness may occur due to transfer on the core side, but the GASEXIT CUSTOM does not causes such unevenness.

Even if the customer cannot modify the mold to the GASEXIT CUSTOM insert , we can also modify the mold.

Inquiry here regarding GASEXIT CUSTOM

「GASEXIT CUSTOM」is able to reduce in molding defects caused by gas and extend maintenance cycle. Please feel free to contact us for inquiries or further discussion about GASEXIT CUSTOM.

Example of a real usage of GASEXIT CUSTOM

I want to improve the uneven coating during painting

Singapore T Company

| Problem |

|

|---|---|

| Countermeasure | 2 GASEXIT CUSTOM were installed on the core side of the product section (near the final filling section) |

| Results |

|

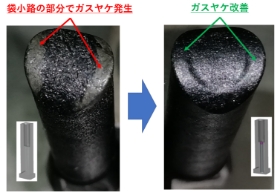

They wanted to improve the gas burn defect at the dead end

Indonesia I Company

| Problem |

|

|---|---|

| Countermasure | Exchanged to the GASEXIT CUSTOM which was manufactured according to the shaft tip shape (3D shape) |

| Results |

|

Inquiry here regarding GASEXIT CUSTOM

「GASEXIT CUSTOM」is able to reduce in molding defects caused by gas and extend maintenance cycle. Please feel free to contact us for inquiries or further discussion about GASEXIT CUSTOM.

Contact

Use the web form for inquiries or quotations.

Please referred to the frequent Q&A before request your inquiries.