Our Strengths

KOEI TOOL is a mold manufacturer with six factories located in Asia, including Osaka.

We specialize in mold design and manufacturing, producing and selling gas venting parts, as well as designing and fabricating metal 3D-printed cooling inserts.

We utilize the capacity of our entire group to accommodate overseas new mold production and maintenance services.

We have a strong track record in manufacturing molds, particularly for design and appearance parts. Additionally, we have introduced metal 3D printers to develop unique gas venting parts for addressing molding defects.

We also offer contract fabrication services for specialized components with challenging shapes that are difficult to achieve through conventional machining methods.

Please feel free to consult with us should you have any specific requirements.

Able to address mold related various needs.

- Mold manufacturing and maintenance locally in South-East Asia.

- End-to-end services for molds, from feasibility study, flow analysis, design, and prototyping.

- Solutions to molding defects caused by gas-related issues.

- Extend the maintenance intervals and increase shot count durability.

- Manufacturing metal 3D printed products from modeling, flow analysis until production.

Strengths of KOEI TOOL

Strengths 01

Maximize manufacturing capabilities by leveraging six group sites in Japan and Asia.

KOEI TOOL has established factories in Japan (Osaka), as well as in Singapore, Thailand, Indonesia, Malaysia, and Vietnam.

Leveraging our extensive manufacturing network across Asia, we offer our customers the opportunity for new mold construction, including quotation, mold consultation, processing, prototyping, and maintenance, at our overseas facilities. Our group's manufactured molds can be maintained and serviced, including mold transfer, at local molding facilities, showcasing a proven track record of successful projects.

We are responsive to specific requirements, such as mold production in Japan and mass production in Thailand, and our overseas representatives strive to provide tailored support based on your needs. This includes local and national staff assistance, ensuring a seamless process from quotations to project completion.

Strengths 02

Turnkey support for mold design to prototyping with expertise in aesthetic mold manufacturing.

Turnkey support for plastic injection mold manufacturing, covering design, mold production, and prototyping. Capabilities extend to injection molding machines up to 350 tons, ensuring top-quality molds.

Specialize in molds for automotive panels, cases, switch components, and small household appliance parts. With expertise in aesthetic parts, excel in high-level polishing techniques and precision mold manufacturing, including double-color and heat & cool molds.

Strengths 03

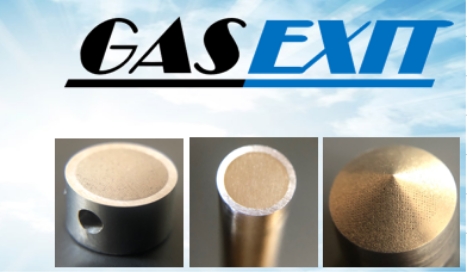

Patented gas venting components「GASEXIT」, solutions for injection molding challenges.

Develop, manufacture, and sell gas venting components 「GASEXIT」that effectively addresses injection molding defects. The product features fine porous material that allows gas to pass through while impeding resin flow. It not only improves molding defects caused by gas but also extends the maintenance cycle of molds and enhances the durability of molds in terms of shot counts.

「GASEXIT」 offers a diverse range of products in various shapes, including runner-type, ejector pin-type, and sprue bush-type. Additionally, as the product is manufactured using metal 3D printing, custom-made gas venting components in different shapes are available to meet specific requirements.

Strengths 04

Two high-precision 3D metal printers capable of comprehensive services from modeling and analysis to actual printing.

KOEI TOOL actively engages in the production of 3D cooling molds using metal 3D printing technology to keep up with evolving mold design and manufacturing techniques. Two state-of-the-art 3D metal printers capable of high-precision fabrication. Utilizing the powder bed fusion method, these printers are ideal for creating intricate internal structures and achieving the precision which otherwise would be difficult with traditional machining methods.

In addition to 3D metal printing, KOEI TOOL handles the entire process from 2D drawings to 3D modeling and flow analysis of 3D cooling inserts. Comprehensive support from comparing both conventional and 3D cooling methods till design and complete mold fabrication. Reliable for the seamless workflow from start to finish.

Contact

Use the web form for inquiries or quotations.

Please referred to the frequent Q&A before request your inquiries.